Proposed Project

|

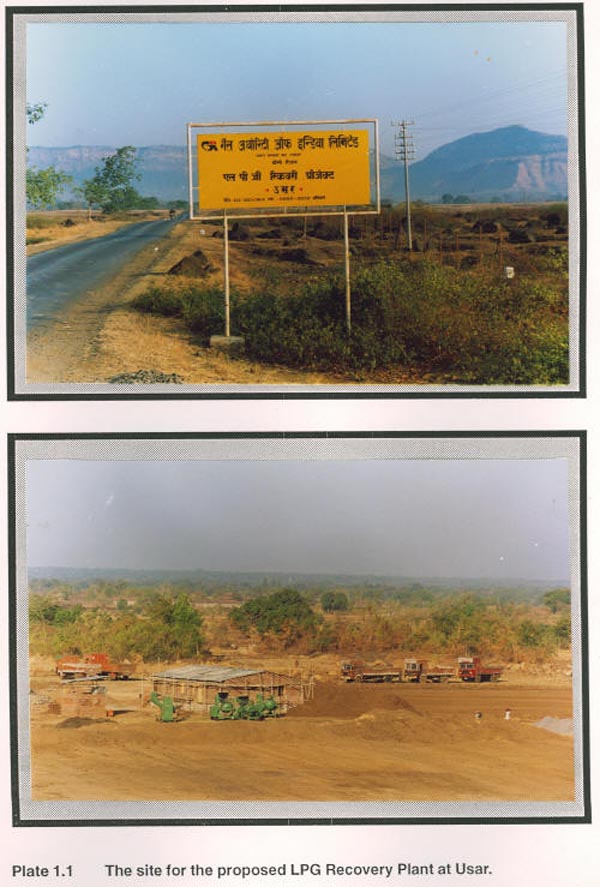

Currently the Oil and Natural Gas Corporation (ONGC) is upgrading its existing facilities at Uran to augment the gas handling capacity. However, in view of the environmental limitations these facilities to handle the gas are restricted to 10.7 MMSCMD to 11.3 MMSCMD. The Gas Authority of India Limited (GAIL) therefore proposed to set up a Liquid Petroleum Gas LPG) Recovery Plant at Usar in Raigad district of Maharashtra. This will facilitate the processing of 5.0 MMSCMD (Million Metric Square Cubic meter per Day) of balance gas recovered from the oil and gas fields of Bombay High. Location The proposed project sire (Plate 1.1) is situated at Usar n(180 36’N and 72058’E) on Alibag Roha road, approximately at 10 km distance from Alibag, the district headquarters of Raigad District (Fig. 1.1). The area that has been acquired for the establishment of LPG Plant is approximately 135ha.

Existing and proposed infrastructural facilities for proposed LPG Plant At present, the Rashtriya Chemical Fertilizer Plant at Thai is receiving the lean gas through an existing 26” pipeline from Bombay High Gas., From Thai this gas shall be taken to the proposed LPG Recovery Plant at Usar. The infrastructure facilities for the proposed LPG Recovery Plant at Usar includes the 21 km long existing pipeline of 26” diameter for supplying gas to RCF Thal from ONGC’s LPG/C2C3 recovery complex at Uran; GAIL’s existing 12” pipeline between Thal and Grasim; and the existing tapping on this pipeline which is ca. 1 km from Usar where the pipeline connection can be made to supply lean gas from Usar, once the plant becomes operational. GAIL also proposes to lay 24” and 20” pipelines, each 16 km long, for receiving gas at Usar from Thal and for supplying lean gas back to RCF Thal respectively. Proposed Lpg Recovery Plant Thal proposed LPG Recovery Plant is based on turboexpander technology for supplying refrigeration to gas. The turboexpander section is preceded by gas drying by molecular sieve and the liquid recovered in turboexpander section is fractioned in two column operators to recover LPG (EIL, 1993). The LPG Recovery Unit consists of the following sections:

Utilities and offsite for Usar LPG Recovery Plant would be provided to cater to the following facilities: a) To provide utilities to the process unit b) To provide receiving, storage and dispatch facilities for chemicals, products etc. The various facilities that would be provided, comprises of the following system:

Product Storage/Dispatch As enumerated by GAIL, following storage and dispatch facilities have been considered: A. Liquid Petroleum Gas (LPG): Three days production equivalent LPG storage shall be provided in the spheres. Total LPG produced will be dispatched by road. B. Natural Gasoline Liquid (NGL): NGL is proposed to be spiked into the lean gas. C. Lean Gas: Lean Gas shall be supplied through 20” pipeline to Thal. |

Last Updated: September 29, 2015