Mining operation

|

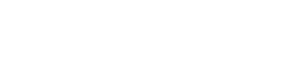

The mining for extraction of limestone from the Babarkot lease hold was initiated in block I of the North block and restricted to North block (Plate 2) where superior limestone was available, conforming to the quality parameters of raw material feed for the cement plant. Two to five benches, 6 to 9 m high, were worked in North block area. The mining was done by open cast method involving drilling, blasting loading by shovels/ pay loaders and transportation through dumpers/ trippers. No overburden was produced as whatever intervening material was excavated along with limestone was used for clinker production. In absence of any overburden available for filling up the void created after extraction of limestone, an artificial fresh water lake over 3.75 ha of mined-out area in the North block has been created. A set of garland drain and check dams guide most of the surface runoff rain water over the whole of the North block area into this lake. This lake serves as a valuable source of sweet water in a water-scarce area, and has helped in charging of the aquifers and improving water availability in wells in the vicinity (Plate 3). This unique effort has not only acted as a valuable source of sweet water in a water-scarce area, but has increased the yield of wells in the neighbourhood

As the working benches went down to the lower horizons of 0 – 6 mRL and 6 – 12 mRL, the quality of limestone deteriorated into marl and inferior grade of limestone. As this lower quality was not suitable for direct raw feed, it became necessary to blend it with limestone of superior quality and the working of the East block for extracting superior grade limestone was initiated. The limestone from East block was also originally mined out by conventional shovel/dumper combination. Since 1995, a surface miner has been deployed in this block (Plate 4). This has not only eliminated the need for drilling and blasting but has also increased the excavation capacity of the mine by 0.8 MTPA. The existing capacity of the mine is now 2.3 MTPA (limestone and marl). The surface miner offered the flexibility of mining near village areas and other areas where drilling and blasting method was not feasible and the technology also allowed mining of different grades of limestone separately to avoid dilution. The overburden in the North block consists of waste material that is back filled in the worked out areas. Topsoil removed is directly utilized for afforestation and reclamation.

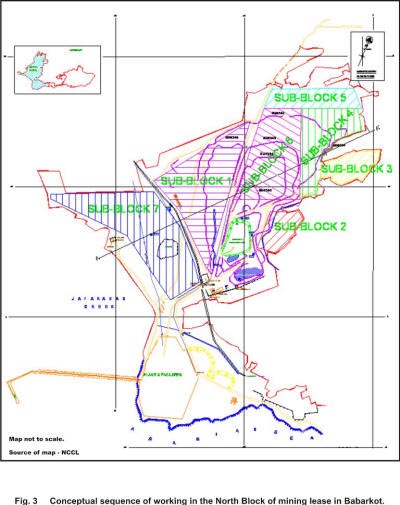

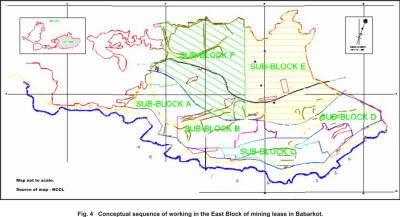

The current position of mine working in North block and East block are shown in conceptual mine plans in Fig. 3 & 4.

In the North block, area on the south of village road, branching off from state highway no. 34 to Babarkot will not be worked as it houses the cement plant. The area South of the present mine office about 175 m wide also will not be worked. Only areas under sand deposits will be removed and exposed limestone will be extracted. The reserves in North block shall be utilized over a period of 14 years. With the exhaustion of the reserves in 14 years, this block will be fully reclaimed by the 20th year. The deposit in the East block will be extracted to a level of 2 mRL. The conceptual sequence of mining in East block is provided in Fig. 4. The reserves in East block shall be utilized over a period of 18 years. |

Last Updated: October 6, 2015